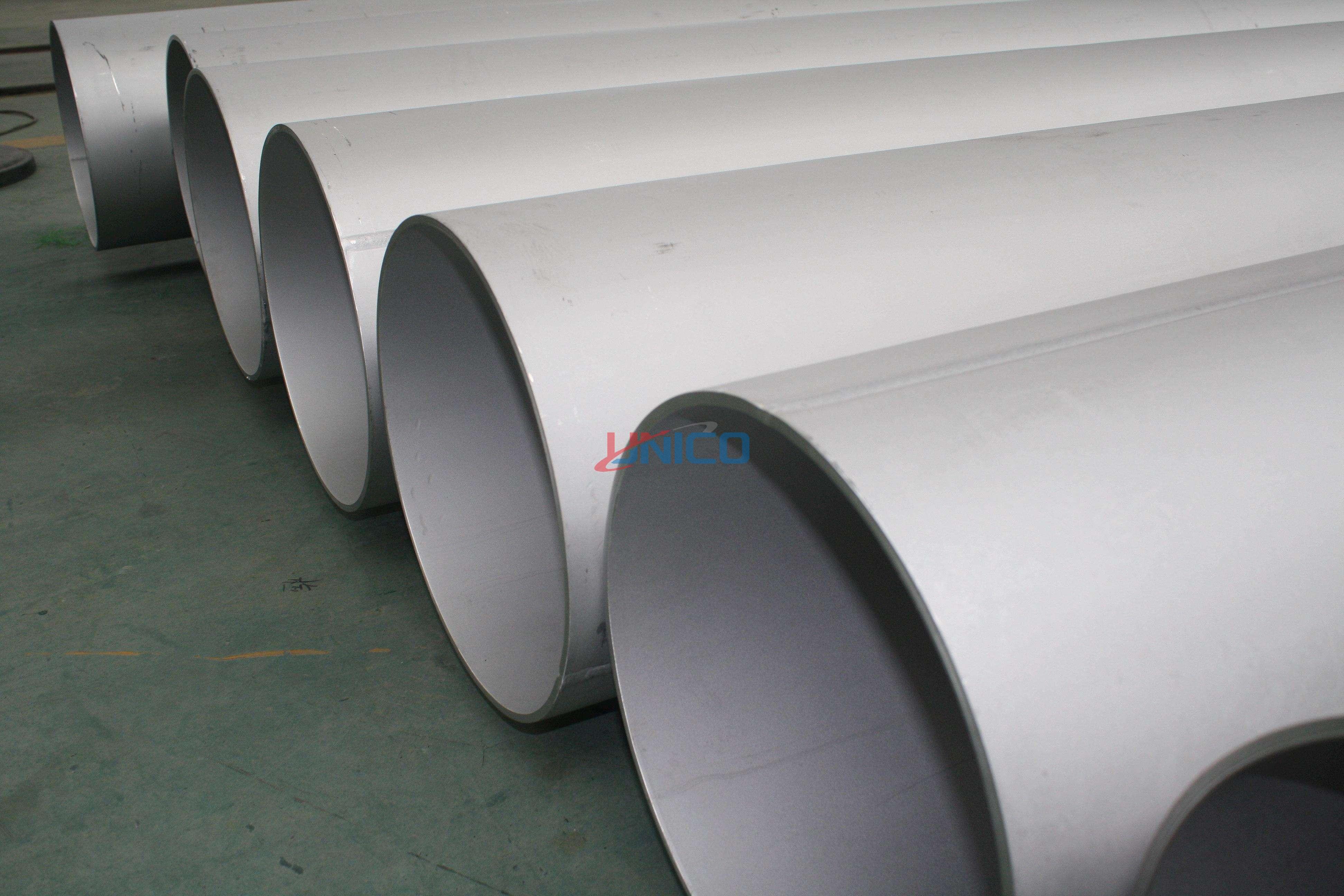

不锈钢焊管

1,Prodution Process

1)Continuous Manufacturing Process of Welded Tubes & Pipes

OD range:. 10-406.4(up to 16") ; WT range: 0.5-10.00 (SCH5S,10S,40S,STD)

2)Bending Process of Welded Pipes

OD range :219.08-2540.00 (up to 100") ; WT range: 3.00-35.00(SCH5S-80S,SCH5-160,STD)

2.用途:石油、石化、炼油、锅炉、化工、机械、电力、造船、造纸、制药、食品等行业。

3.产品标准和范围

| 标准 Standards | 材质 Grades | |||||||||

| 美标ASTM: | A312、A778、A358、A249、A269、A270、A554、A790、A789、A928; | ASTM/ASME: | TP304、TP304L、TP304H、TP316、TP316L、TP321、TP321H、TP310S、TP310H、TP317、TP317L、TP347、TP347H、TP409、TP430、TP444、N08904、S31803、S32205、S32750、S32760 | |||||||

| 日标JIS: | G3459、G3468、G3446、G3463、G3448; | |||||||||

| 欧标EN: | EN10217-7、EN10312 | EN: | 1.4301、1.4306、1.4307、1.4401、1.4404、1.4410、1.4429、1.4462、1.4541、1.4571、1.4539、1.4550 | |||||||

| 德标DIN: | DIN17457、DIN11850 | |||||||||

| 国标GB: | GB/T12770、GB/T12771、GB/T24593、GB/T19228、GB/T21832 | GB/HG: | 12Cr18Ni9、06Cr19Ni10、022Cr19Ni10、07Cr19Ni10、06Cr23Ni13、06Cr25Ni20、06Cr17Ni12Mo2、06Cr19Ni13Mo3、022Cr19Ni13Mo3、06Cr18Ni11Ti、06Cr18Ni11Nb、07Cr18Ni11Nb、022Cr22Ni5Mo3N、022Cr23Ni5Mo3N、022Cr25Ni7Mo4N | |||||||

| HG: | HG20537.1、HG20537.2、HG20537.3、HG20537.4 | |||||||||

| 其他非标产品可以根据客户技术要求订制承接。 | 其他材质可以根据客户技术要求,进行PQR后判定承接. | |||||||||

| Non-Standard products are available upon customer requirements. | Other Grades are available upon customer requirements after PQR. | |||||||||

| 生产工艺类别 Prodution Process | 外径 OD | 壁厚 MT | 长度 Length | |||||||

| (mm) | (mm) | (mm) | ||||||||

| 连续成型生产工艺的产品 Continuous Manufacturing Process of Welded Tubes & Pipes | 10-406.4 (up to 16") | 0.5-10.00 (SCH5S,10S,40S,STD) | 2000-18000 (online cutting) | |||||||

| 单支成型生产工艺的产品 Bending Process of Welded Pipes | 219.08-2540.00 (up to 100") | 3.00-35.00 (SCH5S-80S,SCH5-160,STD) | 1500, 2000 6000, 12000 | |||||||

.png)